Furnace Lining Construction

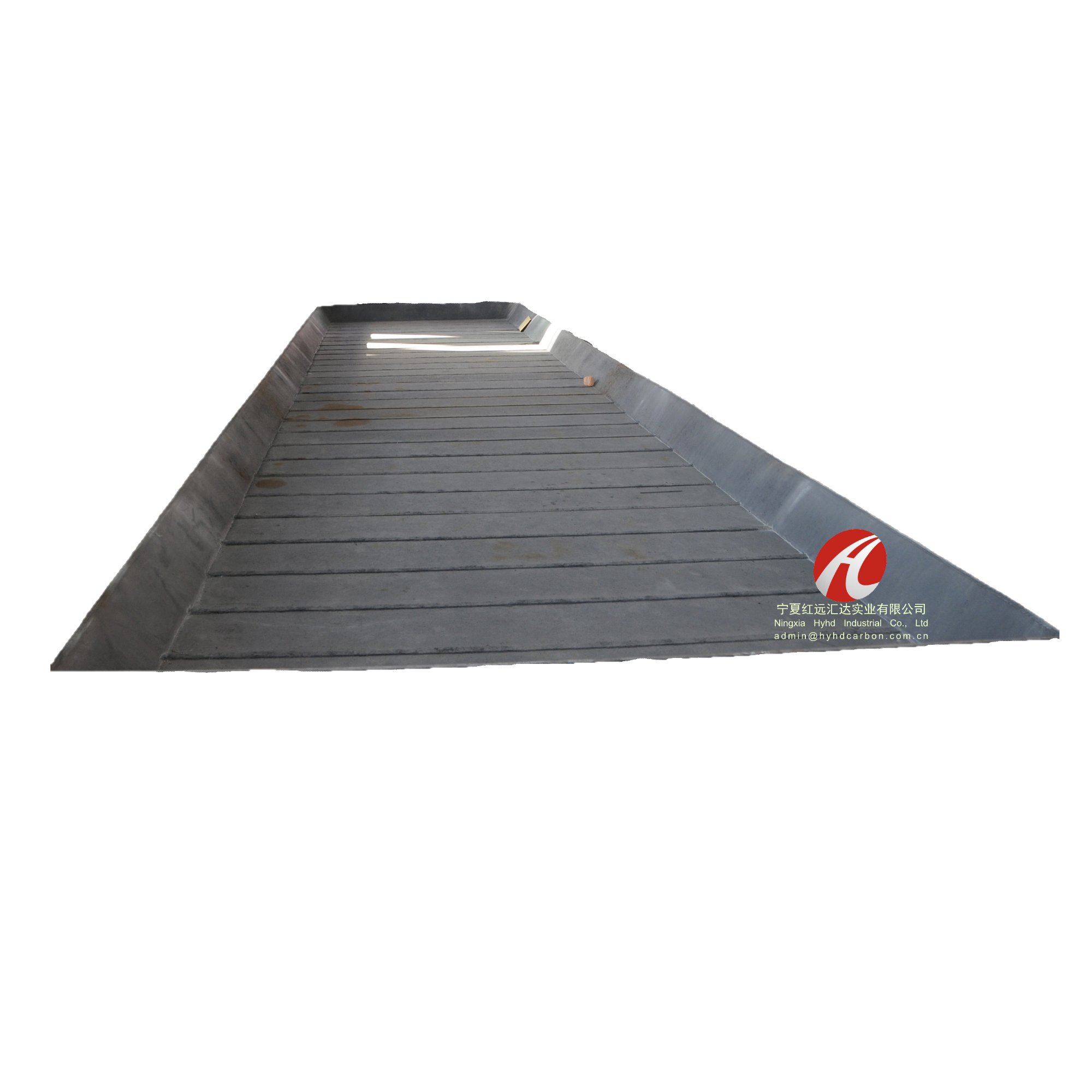

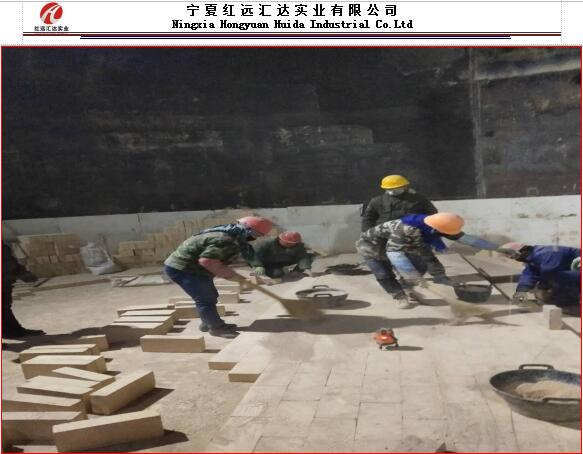

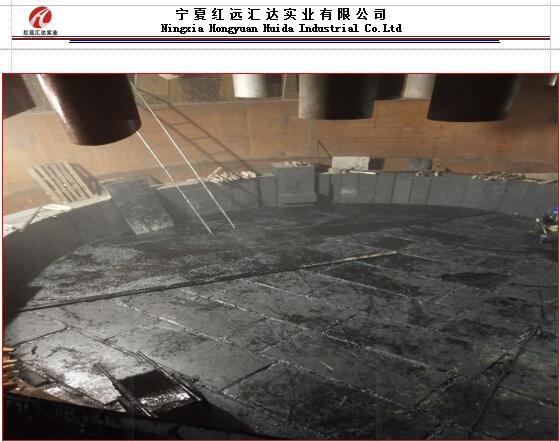

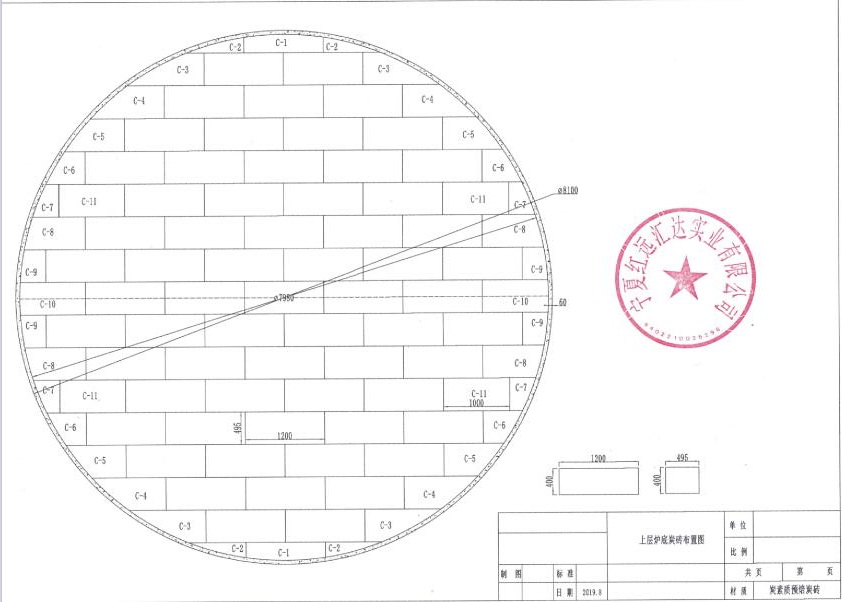

Construction Case of Overall Furnace Lining.

Ningxia Hongyuan Huida Industrial Co.,Ltd not only provides furnace lining construction materials, but also provides

technical guidance for furnace lining construction.

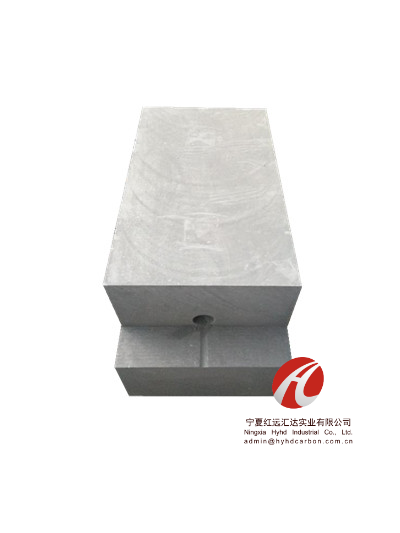

Furnace lining construction mater